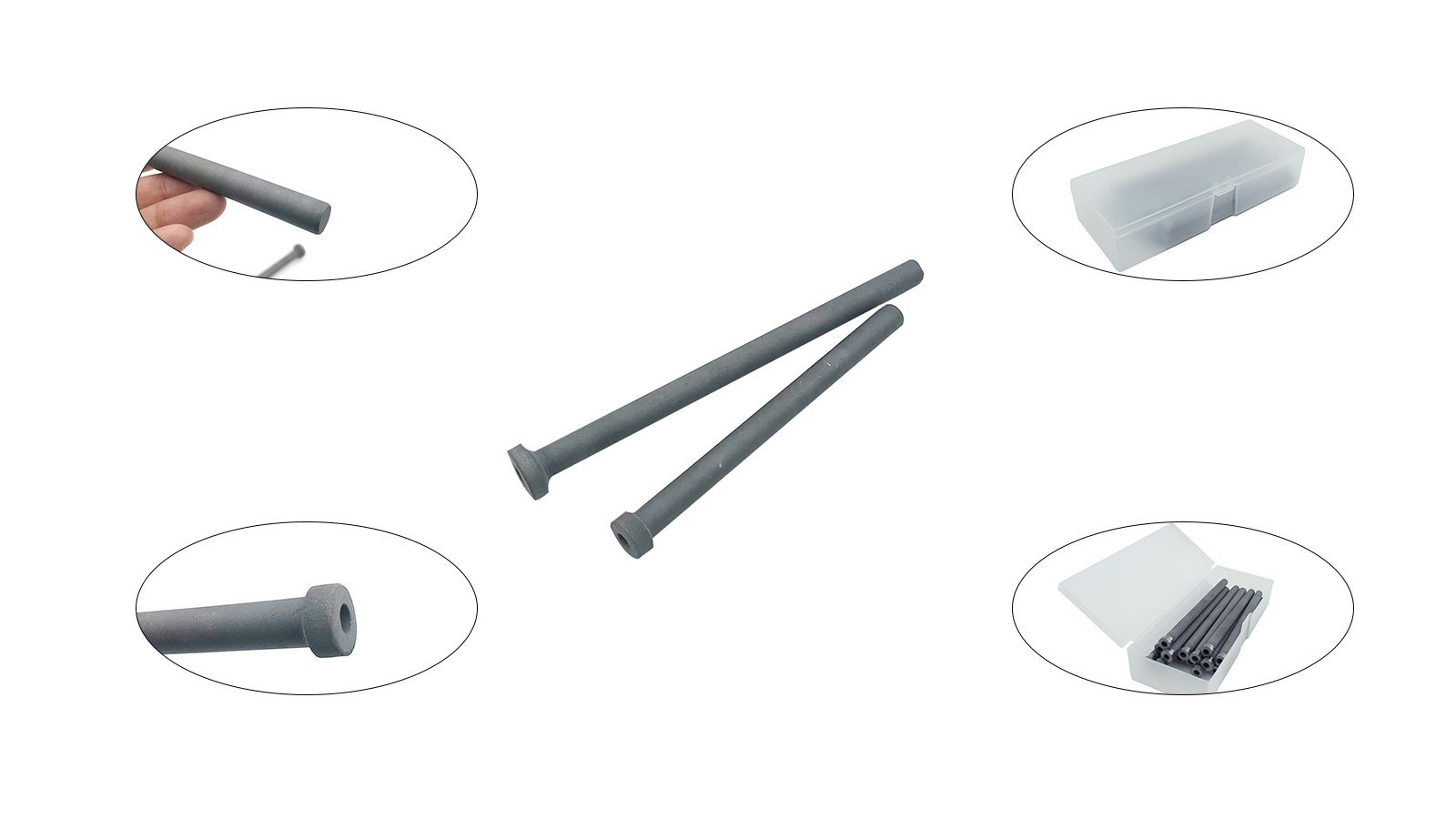

Molten steel temperature measurement thermowell

2023-02-23 11:39How to choose a good thermowell?

The choice of thermowell depends on the specific application requirements, such as the type of process fluid, the temperature range, the pressure range, and the process environment. Generally, a good thermowell should:

Provide adequate protection: The thermowell should protect the temperature sensor from the process fluid, which can be corrosive, abrasive, or otherwise damaging.

Be compatible with the process fluid: The thermowell material should be compatible with the process fluid to avoid corrosion or contamination.

Withstand high pressures and temperatures: The thermowell should be able to withstand the high pressures and temperatures present in the process.

Be durable: The thermowell should be able to withstand wear and tear over a long period of time.

Provide accurate temperature measurement: The thermowell should not affect the accuracy of temperature measurement and should minimize the lag time between changes in temperature and the temperature sensor reading.

Be easy to install and maintain: The thermowell should be easy to install, remove, and maintain.

Some common types of thermowells include:

Threaded thermowells: These are threaded into the process and are available in various sizes and materials.

Flanged thermowells: These are flanged onto the process, which makes them easier to remove for maintenance.

Weld-in thermowells: These are welded into the process and are often used in high-pressure or high-temperature applications.

Sanitary thermowells: These are designed for use in sanitary applications, such as in the food and beverage industry, and are typically made of stainless steel.

The selection of a good thermowell depends on the specific requirements of the application and the environmental factors present in the process.

Molten steel temperature measurement

Molten steel temperature measurement is a critical process in steel manufacturing, and accurate temperature measurement is important for ensuring the quality of the final product. To measure the temperature of molten steel, a thermowell is typically used to protect the temperature sensor from the extreme heat and corrosive environment of the molten steel.

Molten steel temperature measurement is a critical process in steel manufacturing, and accurate temperature measurement is important for ensuring the quality of the final product. To measure the temperature of molten steel, a thermowell is typically used to protect the temperature sensor from the extreme heat and corrosive environment of the molten steel. The thermocouple is inserted into the thermowell and connected to a temperature monitoring system.

The thermowell used for molten steel temperature measurement is typically made of a high-temperature and corrosion-resistant material such as ceramic. These materials are able to withstand the high temperatures of molten steel, which can range from 1500°C to 1700°C. And the thermowell must be able to withstand the thermal shock caused by the rapid changes in temperature when it is immersed in the molten steel. The thermowell must also be able to withstand the pressure caused by the weight of the molten steel. So the design of the thermowell is very important.