- Home

- >

News

SYTOP customized a nested cobalt alloy wearing bush solution (ST12 threaded bush + ST6 lower flange bush) for centrifugal pumps in the paper & pulp industry. Designed for highly abrasive and erosive pulp media, this dual-layer structure significantly extends pump service life, reduces maintenance downtime, and improves production stability.

January 6, 2026, a batch of customized cobalt alloy seaming rolls has passed rigorous quality inspections and is now ready for delivery to a world-renowned can manufacturing precision tool enterprise.

SYTOP successfully completed and shipped a customized order of T800, ST4, and ST6 cobalt-based alloy bushings for a global hot-dip galvanizing enterprise, delivering high-precision, application-specific solutions that improve service life, reduce downtime, and support stable CGL operations.

With tungsten prices surging, carbide saw tips are no longer cost-effective. Discover how cobalt alloy saw tips deliver comparable costs, longer service life, and direct replacement for tungsten carbide in modern sawmill operations.

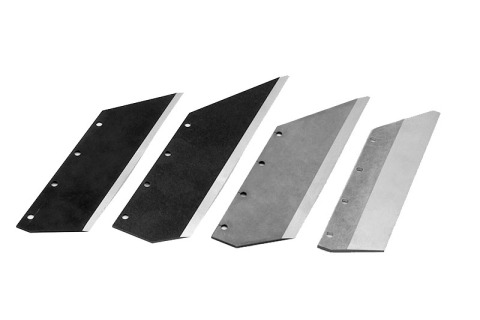

Discover why cobalt alloy scissor blades are the premium solution for cutting molten glass at 1000°C. With exceptional red hardness, superior wear resistance, and outstanding corrosion protection, cobalt alloy shears ensure smooth, defect-free glass bottles for pharmaceutical, food, and cosmetic applications.

SYTOP announces a major breakthrough in Cobalt Alloy 6K (ST 6K) rolling technology, becoming one of the few manufacturers capable of mass-producing high-carbon cobalt alloy rolled sheets in China. This advancement overcomes long-standing technical barriers, enhances material density and mechanical stability, and provides reliable local supply for industries such as viscose fiber cutting, food processing machinery, chemical equipment, aerospace, and high-end manufacturing.

Learn why cobalt-based alloys are the preferred material for dies used in the engine valve electrothermal upsetting process. Discover their advantages in high-temperature stability, wear resistance, anti-seizure performance, and how they improve valve forming accuracy and tool life.

Learn what a piston valve housing is, its purpose in oil & gas systems, and why cobalt alloy materials outperform cast iron and stainless steel under extreme temperature, pressure, and corrosion. Discover performance advantages, material comparisons, and selection guidance for high-reliability valve housings.

The cobalt alloy valve cage is a critical component in deep oil well operations, offering excellent wear, corrosion, and high-temperature resistance. SYTOP manufactures precision-cast valve cages in grades ST6 and ST19 to ensure long-lasting performance under extreme pressure and abrasive conditions.

Learn how cobalt alloy blades enhance efficiency and reliability in tomato paste production lines. With exceptional wear and corrosion resistance, ST 6K blades and overlay services provide long-lasting performance for food processing equipment such as pulpers and scrapers.

Learn how cobalt alloy cutting blades outperform HSS and carbide in viscose fiber production with superior wear, corrosion, and chipping resistance, ensuring stable, high-quality output.

Cobalt alloys enhance paper vibrating screens with superior wear, corrosion, and heat resistance, extending component life, ensuring stable operation, and improving production efficiency.