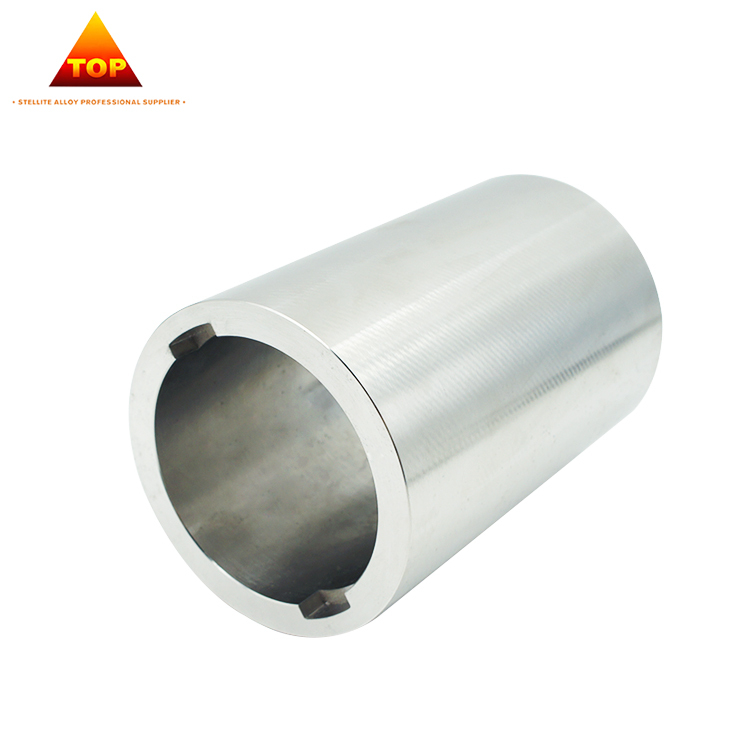

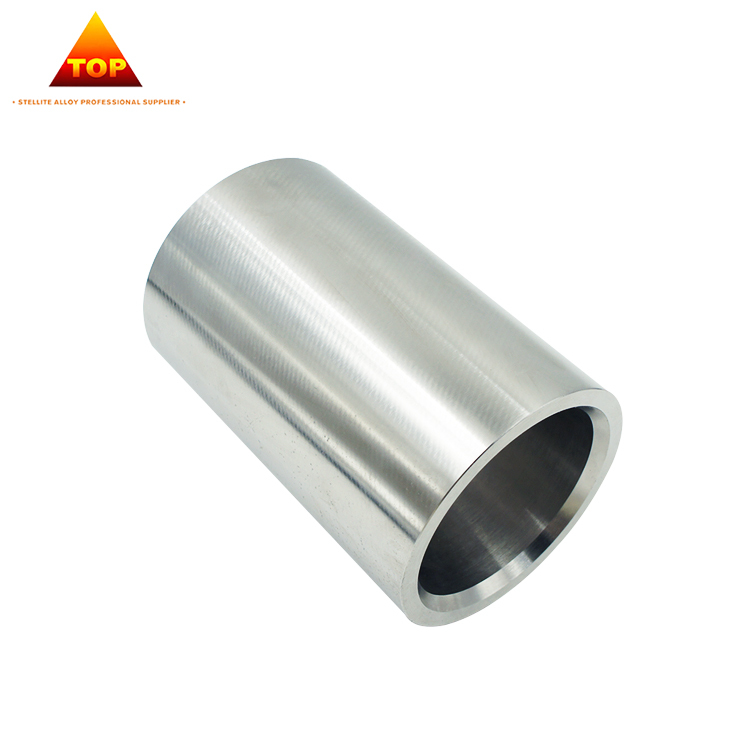

Cobalt Alloy Bushing Bearing Bush

Cobalt Alloy Bushing Bearing Bush offers unparalleled durability and reliability in high-wear applications, such as heavy machinery, automotive, and aerospace. Engineered with advanced materials and precision manufacturing, our bushings exceed industry standards.

- TNM

- China

- 25-50days

- 20000pcs/month

- Information

Cobalt Alloy Bushing Bearing Bush Cobalt Sleeves

Cobalt Alloy 6 bushing and sleeve are the advantaged products for us , we have produced more than thousands specifications and all of them are produced upon customer’s drawing.

Advantages

Cobalt Alloy 6 is a cobalt-based alloy that is known for its excellent wear resistance, high-temperature resistance, and corrosion resistance.

Wear resistance: ST6 has excellent wear resistance due to the combination of high hardness and toughness.

High temperature resistance: ST6 can withstand high temperatures without losing strength and wear resistance.

Corrosion resistance: ST6 is highly resistant to corrosion, making it suitable for use in harsh environments.

Applications

Pump and valve components: ST6 bushings are commonly used in pumps and valves due to their wear resistance and corrosion resistance.

Bearing applications: ST6 bushings are used in bearing applications that require high wear resistance and durability.

Aerospace applications: ST6 is used in aerospace applications such as turbine blades and exhaust valves due to its high temperature resistance.

Oil and gas industry: ST6 bushings are used in the oil and gas industry for downhole drilling applications due to their wear resistance and corrosion resistance.

Now we could supply many kinds of cobalt alloy bushing, we can also supply 316L and cobalt composite structure sleeve and ceramic with 316L composite structure sleeve .

ST6 bushings Brief information.

Process : | Powder Metallurgy , it is short for PM and investment casting |

Hardness: | 38 - 44 HRC |

Density : | 8.35 g/cm ³ |

Size : | Diameter 8-500mm and maxium length 500mm

|

Properties : | Wear and corrosion resistance, high temperature resistance |

Instructions : | Drawing made upon cutomers request |

Tolerance control : | turning or grinding surface , tolerance upon drawing |

Production lead time | normal order 30 days |

Production capacity : | 20,000pcs one month. |

Package : | carton or wooden case , pallet for export |

Material Choose | Typical Application | Process |

Cobalt Alloy 6(ST6) | Hot-dip galvanized production line used bushing ,sink roll and sleeve and bearing bush

| Powder metallurgy & investment casting

|

Cobalt Alloy 4(ST4) | ||

Tribaloy 400 | ||

Tribaloy 800 |

Production Process:

Powder preparation: The ST6 powder is prepared by mixing cobalt, chromium, and tungsten carbide powders in the desired proportions.

Blending: The ST6 powder is blended using a ball mill or a mixer to ensure that the powders are homogeneously mixed.

Compaction: The ST6 powder is compacted using a hydraulic press or a mechanical press. The compacted powder is called a green compact.

Sintering: The green compact is sintered in a furnace at a high temperature of around 1200-1300°C. During sintering, the powder particles are bonded together to form a solid material.

Machining: The sintered ST6 bushing is machined to achieve the desired shape and dimensions.

Finishing: The ST6 bushing is finished by polishing or coating it to improve its surface properties.

Best service

1. Samples could be supplied for testing at first

2. Flexible order ,there is no MOQ request .

3. Professional technical team and engineers to support us .

Please contact us and send inquiries .