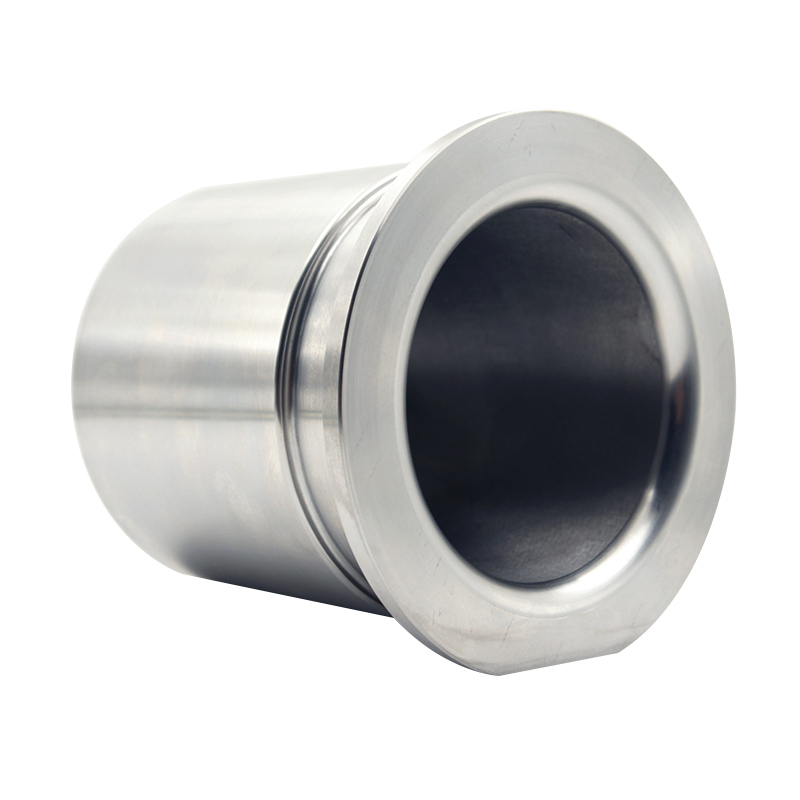

Cobalt Alloy Grade 4 Sleeve

SYTOP Cobalt Alloy Grade 4 Sleeve is used in hot dip galvanizing lines, resistance for high-temperature, wear, and corrosion protection in steel manufacturing.

- TNM

- China

- 45days

- 100pcs/month

- Information

- Video

Cobalt Alloy Grade 4 Sleeve Used in Hot dip galvanizing production line

Hot-dip galvanizing is a form of galvanizing. In the process of applying zinc to steel, when the metal is immersed in a bath of molten zinc at a temperature of approximately 450 °C (842 °F), the zinc forms with the surface of the base metal a measure that protects the steel from further corrosion.

In the process of galvanizing, some equipment parts of the galvanizing line need to work in high-temperature zinc solution or zinc-aluminum solution for a long time, so a material that can have high-temperature resistance, corrosion resistance and wear resistance at the same time is required. Stellite alloy perfectly solves this problem and provides a good solution for galvanized production equipment components.

NOMINAL CHEMICAL COMPOSITION (MASS%)

Alloy | C | Mn | Si | Cr | Ni | Mo | W | Co |

Cobalt Alloy Grade 4 | 0.8-1.3 | ≤1.0 | ≤1.5 | 28.0-32.0 | ≤3.0 | ≤1.5 | 12.5-15.5 | bal. |

Cobalt Alloy Grade 4 sleeves Brief information.

Process : | Powder Metallurgy(PM) and investment casting |

Hardness: | 40-46 HRC |

Density : | 8.65 g/cm ³ |

Size : | Diameter 50-300mm and maxium length 300mm

|

Properties : | Wear and corrosion resistance, high temperature resistance |

Instructions : | Drawing made upon cutomers request |

Tolerance control : | turning or grinding surface , tolerance upon drawing |

Production lead time | normal order 45 days |

Production capacity : | 200pcs one month. |

Package : | carton or plywood package, and pallet for export |

Material Choose | Typical Application | Process |

Cobalt Alloy Grade 6 | Hot-dip galvanized production line used bushing ,sink roll and sleeve and bearing bush

| Powder metallurgy & investment casting

|

Cobalt Alloy Grade 4 | ||

Cobalt Alloy T 400 | ||

Cobalt Alloy T 800 |

Production Process:

Best service

1. Samples could be supplied for testing at first

2. Flexible order ,there is no MOQ request .

3. Professional technical team and engineers to support us .

Please contact us and send inquiries .