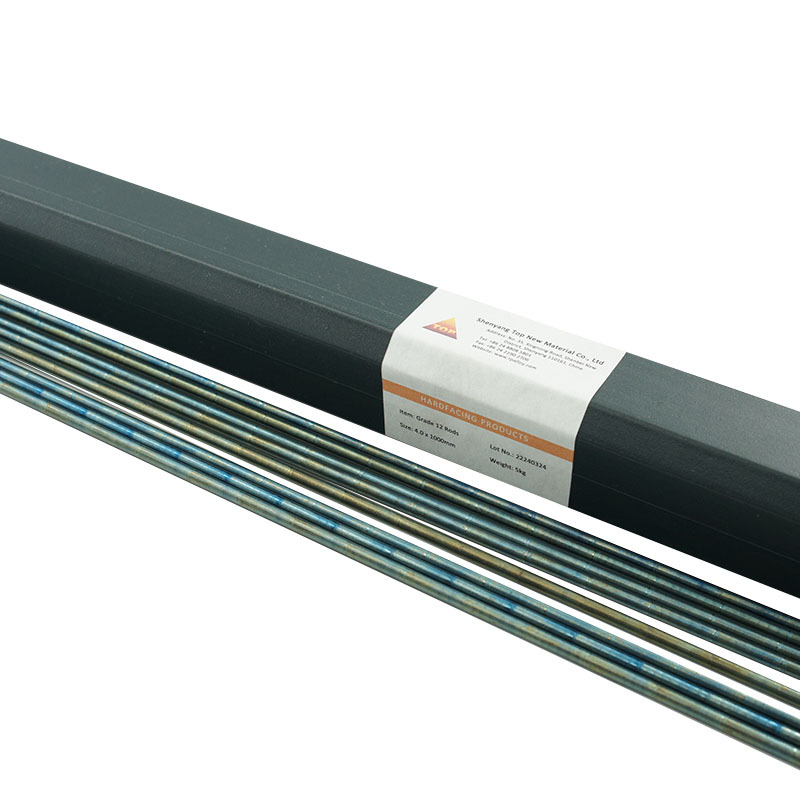

AWS A5.21 ERCoCr-E Cobalt Alloy 21 Welding Rods

AWS A5.21 ERCoCr-E Cobalt Alloy 21 Welding Rods for demanding welding applications. These rods are crafted from continuous casting, offering superior strength, corrosion resistance, and thermal stability. With precise manufacturing and adherence to AWS standards, our welding rods ensure reliable and consistent welds in a variety of environments.

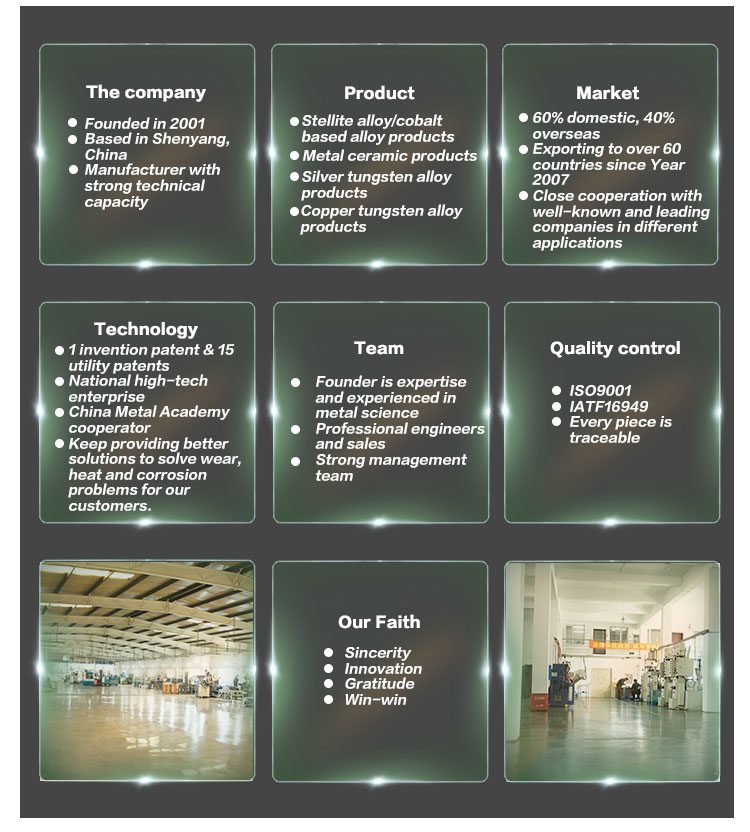

- TNM

- China

- 1 week

- 5000kgs+/month

- Information

AWS A5.21 ERCoCr-E Cobalt Alloy 21 Welding Rods

AWS A5.21 ERCoCr-E welding rods are a type of welding electrode used specifically for welding or repairing cobalt alloy 21 alloys. ST 21 is a cobalt-based alloy that contains high amounts of chromium, tungsten, and molybdenum, making it highly resistant to corrosion and wear. It is often used in high-temperature and high-wear applications such as valve seats, bearings, and cutting tools.

ST 21 welding rods are designed to have a similar composition to ST 21, ensuring that the welding process produces a high-quality weld that retains the desired properties of the alloy. These welding rods can be used with various welding processes, including TIG (tungsten inert gas) welding and plasma welding, to create a strong and durable weld joint.

ST 21 welding rods are available in different diameters and lengths to suit different welding applications and requirements.

Cobalt Alloy Welding Rod is supplied in the following forms:

As-Cast: Meets most hardfacing requirements.

Densified: Hipped to eliminate centerline porosity.

Ground/Finished: Eliminates surface imperfections.

Applicable Processes:

Oxy-Acetylen Tungsten Inert Arc (TIG)

Standard rod diameters include:

2.7 mm

3.2 mm

4.0 mm

4.8 mm

5.0 mm

6.0 mm

6.4 mm

Note: Additional diameters, rod lengths(normally length is 1m, 2m and 4m), and packaging available upon request.

Advantages of Cobalt Alloy welding rods:

Produced by horizontal continuous casting.

Excellent surfacing performance.

Has good high temperature strength and good wear resistance, high-temperature resistance, impact resistance and certain corrosion resistance.

Applications:

Argon arc welding, oxyacetylene welding, etc.

It can be used for surface treatment of parts and components in extrusion dies, turbine blades, exhaust valves of internal combustion engines, oil drilling tools, marine engineering, petroleum industry, coal, oil refining, chemical engineering, boilers and other industries.

Chemical compositions and properties (%)

| Brand | C | Mn | Si | Cr | Ni | Mo | W | Co | Fe | Hardness(HRC) |

| ST 1 | 2.2-2.8 | - | ≤2.0 | 29.0-33.0 | ≤3.0 | ≤1.0 | 11.0-14.0 | Bal. | ≤3.0 | 51-55 |

| ST 6 | 0.9-1.4 | 1.0 | ≤1.5 | 27.0-31.0 | ≤3.0 | ≤1.5 | 3.5-5.5 | Bal. | ≤3.0 | 38-44 |

| ST 12 | 1.1-1.7 | 1.0 | ≤1.0 | 28.0-32.0 | ≤3.0 | - | 7.0-9.5 | Bal. | ≤3.0 | 44-49 |

| ST 21 | 0.15-0.4 | 1.0-2.0 | ≤1.0 | 26.0-38.0 | 2.5 | 5.0-6.0 | - | Bal. | ≤3.0 | 27-40 |

SYTOP cobalt-based alloy is a range of cobalt-chromium-tungsten alloys with wear resistance, corrosion and high thermal resistance. It is widely used in oil & gas, machinery, wood cutting, automotive, paper and food processing industry etc.

Other products that we can made :

Different size bars, rods, plate, sheets

Drawing made seal rings, valve seats and balls , bushes and sleeves etc.

Some size tube

D1.2mm Welding wire

Most of our products are made upon customers' request so contact us right now for personal and professoinal service.

More details about cobalt chrome round bar please do not hesitate to contact me .