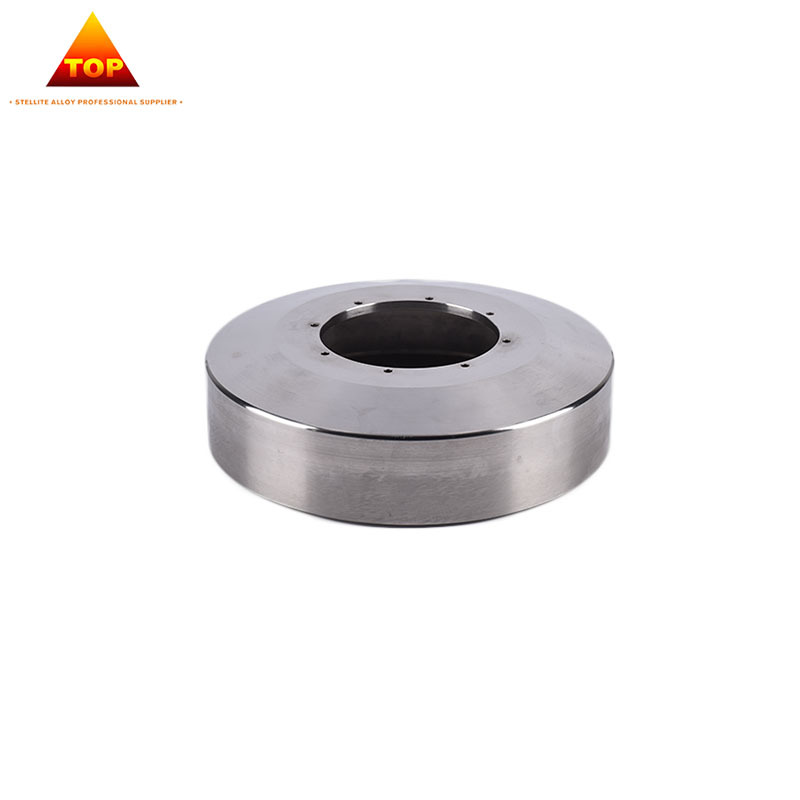

Cobalt Spinner Discs

When fiberizing glass wool is produced by the centrifugal process, the spinner discs is the main part of the centrifuge. SYTOP supply Cobalt based and Nickle based spinner discs. The cobalt-based alloy centrifugal spinner disc has an average service life of 300 hours.

- SYTOP

- China

- 20-30days

- 2000pcs/month

- Information

What is the Details of SYTOP Cobalt Chrome Centrifugal Spinner Disc?

Material : | Cobalt and nickel base alloy |

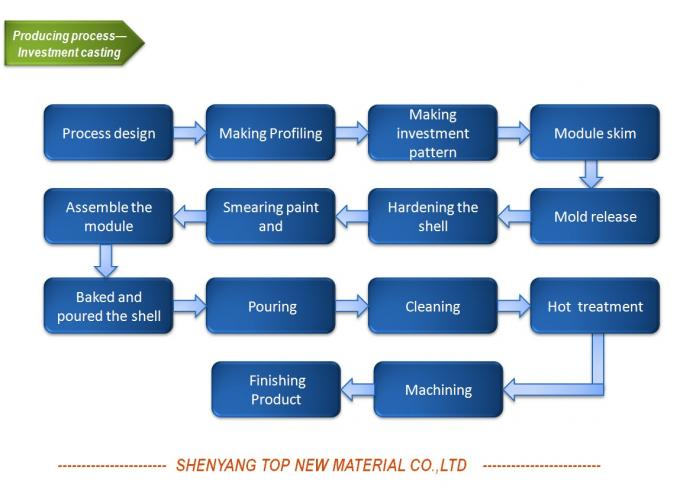

Process : | Investment castings |

Application : | Glass wool industry |

Density : | 8.4 g/cm ³ |

Overall dimensions : | φ200~500mm

|

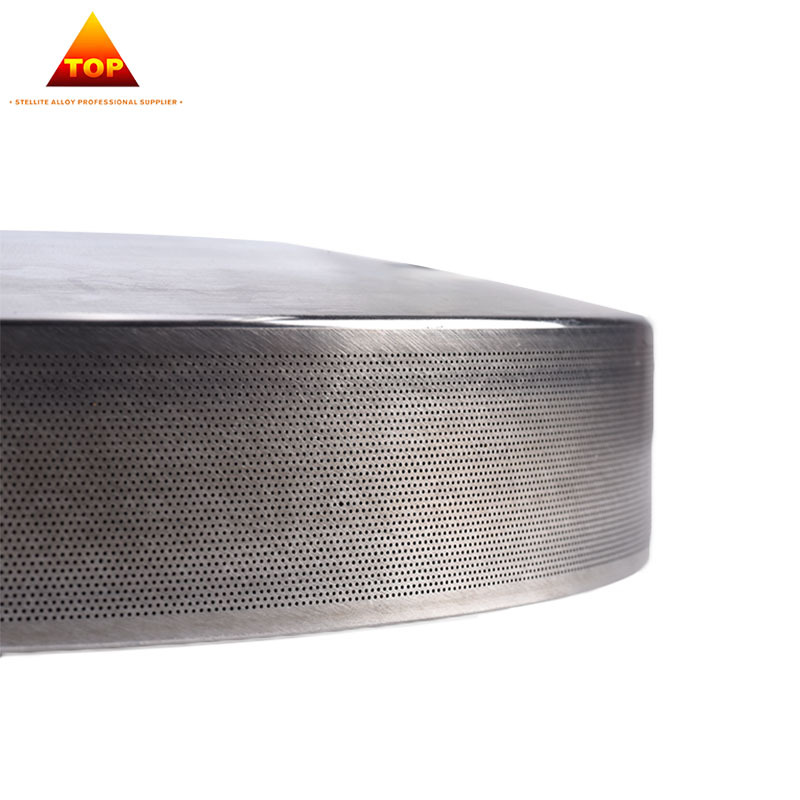

Hole dimensions: | φ0.5~1.0mm |

Holes amount: | 7000~33000 units |

Operating temperature: | 1050°C |

Rotating speed: | ≤3000 r/min |

Tolerance control : | grinding surface , tolerance upon drawing |

Fiber dimensions: | ≤7μm |

Lifetime: | ≥300 hours |

Package : | carton or wooden case , pallet for export |

Chemical Components & Physical Properties

Grade NO. | Chemical Components | Physical Properties | ||

Density (G/cm3)≥ | Hardness HRC≥ | Elongation Mpa≥ | ||

TPM10 | C CR NI W 0.4 30 50 15 | 8.3 | 35 | 700 |

2.4879 | C CR NI W Fe 0.4 28 48 5 Bal. | 8.3 | 400 | |

CoCrW31 | C CR NI W Co 0.5 26 1 0.5 7.5 Bal. | 8.5 | 32 | 735 |

Production process

Application :

Blowing glass wool production line

When fiberizing glass wool is produced by the centrifugal process, the spinner discs is the main part of the centrifuge.

The service life of the spinner discs directly affects the quality, efficiency and cost of the glass wool product. The product uses nickel-based high-temperature alloy and cobalt-based high-temperature stainless steel as materials.

It has high high-temperature durable fracture strength and high temperature creep resistance, excellent high temperature oxidation resistance, molten glass corrosion and erosion resistance, and good machining performance.

Shenyang Top New Material Co., Ltd. is a manufacturer producing cobalt based alloy over 20 years.

The spinner discs casting fiberized produced by our company are positioned at high-end quality, mainly exported abroad, and have obvious quality advantages compared with other peer products

The small holes are resistant to high temperature erosion by glass liquid, have long service life, and have good resistance to high temperature creep deformation.

The original spinner discs is affected by high-temperature centrifugal force. The height of the spinner discs is reduced and the middle diameter is enlarged into a waist drum shape, which affects the centrifugal glass wool The forming principle.

The castings are made from cobalt based alloys or nickel based alloys, regular diameters ranges from OD200 to OD500mm, like Φ300mm, Φ303mm, Φ320mm, Φ360mm, Φ380mm, Φ390mm, Φ400mm, Φ406mm etc.

Our company can process and manufacture according to your drawings. Please indicate the diameter and the number of holes when ordering. A quotation will be given according to the drawings and specifications