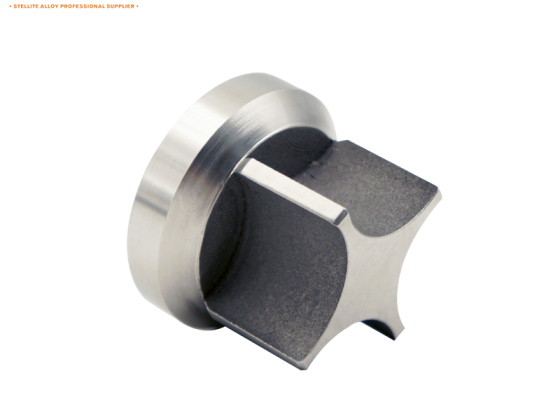

Cobalt Alloy Seaming Rollers for Can Sealing Machine

SYTOP Cobalt Alloy Sealing Rollers are engineered for can seaming machines or can seamers. Seaming rolls offer wear and corrosion resistance. Your production lines will achieve maximum uptime and consistent seam quality in acidic food processing and high-speed operations by using cobalt alloy 20 sealing rollers.

- SYTOP

- China

- 30-60 days

- 1000pcs/month

- Information

Extreme Wear Resistance: The high tungsten and carbon content of Cobalt Alloy 20 (56-60 HRC) provides superior protection against abrasive wear from tinplate and aluminum cans.

Superior Red Hardness: Maintains exceptional mechanical properties and hardness at high local frictional temperatures (up to 400°C).

Food-Grade Corrosion Resistance: Excellent resistance to organic acids, brines, and harsh CIP (Clean-in-Place) chemicals, ensuring zero contamination.

Anti-Galling & Mirror Finish: Precision-ground grooves prevent "Angel Hair" (metal slivers), ensuring smooth sealing and reduced scrap rates.

Extended Service Life: Outlasts standard stainless steel and D2 tool steel rollers by 5 to 10 times, resulting in significantly lower Total Cost of Ownership (TCO).

Technical Specifications

| Property | Detail |

| Material Grade | ST 20(Cobalt Alloy) |

| Mail Elements | Co (Base), Cr (30-34%), W (14-19%), C (2.0-3.0%) |

| Hardness | 56-60 HRC |

| Density | 8.7g/cm³ |

| Custom | Accept |

Application & Equipment

Beverage Canning: High-speed lines for beer, carbonated drinks, and juices.

Food Packaging: Processing lines for tomato paste, fish, meat, and acidic vegetables.

Aerosol & Chemical: Seaming for industrial aerosol cans and chemical containers.

Equipment Focus: Ideal for Automatic Double Seamers and Closing Machines.

Custom Engineering: We manufacture custom ST 20(Coblat Alloy) rollers based on your technical drawings (e.g., for Maiko or Angelus profiles).

Material Integrity: Every batch is tested via Spectrographic Analysis to ensure 100% alloy compliance.

Precision Manufacturing: Advanced CNC grinding technology ensures the exact profile geometry required for perfect "Double Seam" integrity.