- Home

- >

News

Discover why cobalt alloy scissor blades are the premium solution for cutting molten glass at 1000°C. With exceptional red hardness, superior wear resistance, and outstanding corrosion protection, cobalt alloy shears ensure smooth, defect-free glass bottles for pharmaceutical, food, and cosmetic applications.

Learn how cobalt alloy blades enhance efficiency and reliability in tomato paste production lines. With exceptional wear and corrosion resistance, ST 6K blades and overlay services provide long-lasting performance for food processing equipment such as pulpers and scrapers.

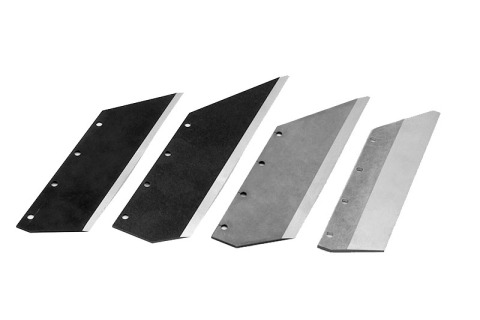

Learn how cobalt alloy cutting blades outperform HSS and carbide in viscose fiber production with superior wear, corrosion, and chipping resistance, ensuring stable, high-quality output.

In polymer processing, underwater pelletizing systems have become the go-to choice for improved efficiency, quality, and sustainability, outperforming traditional methods. But their success depends entirely on one key part: the pelletizing blade. SYTOP designs high-performance blades tailored to unlock the full power of these systems.

Cobalt Alloy 6 offers exceptional high-temperature wear resistance, corrosion resistance, and toughness, making it ideal for turbine blades, combustion chambers, valves, bearings, and sealing surfaces in aerospace engines.

Steam turbine blades operate in extreme environments with high temperatures, corrosive media, and mechanical stresses. Over time, corrosion and wear degrade blade performance, leading to efficiency losses and costly maintenance. To address these challenges, Alloy 6B/UNS R30016 is a superior material for wear strips and protective overlays on steam turbine blades. This cobalt-chromium-tungsten alloy complies with AMS 5894, combining unmatched corrosion resistance, high-temperature stability, and mechanical durability. This article explores the root causes of turbine blade corrosion and the criteria for material selection.

May 15th to May 19th, 2023, Hall 15, 77/2. LIGNA is one of the most important trade shows for the woodworking and wood processing industry and it is scheduled to take place in Hannover.