AWS A5.21 Cobalt Alloy 12 welding rods

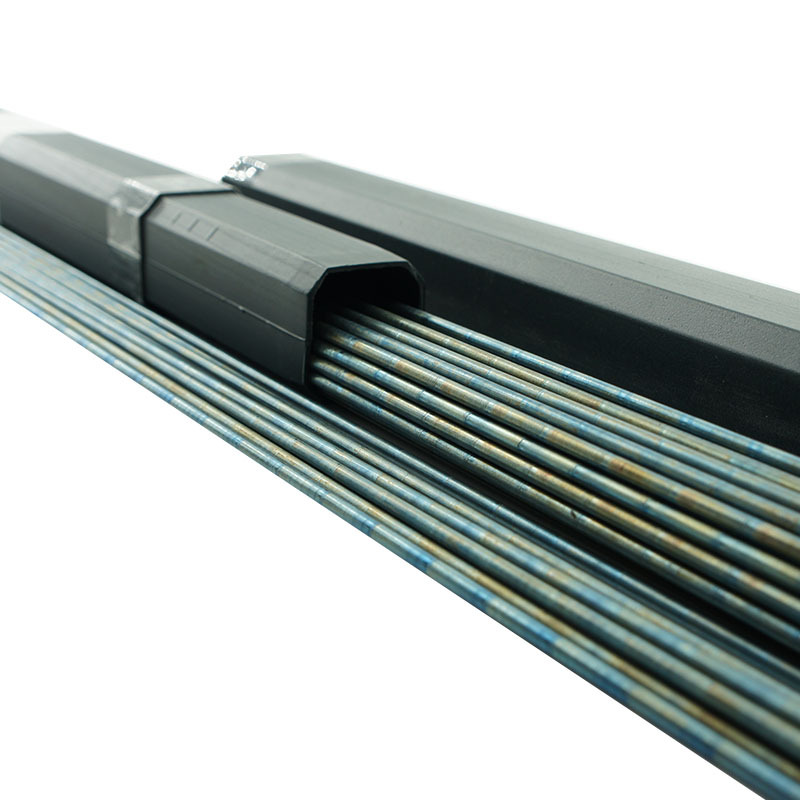

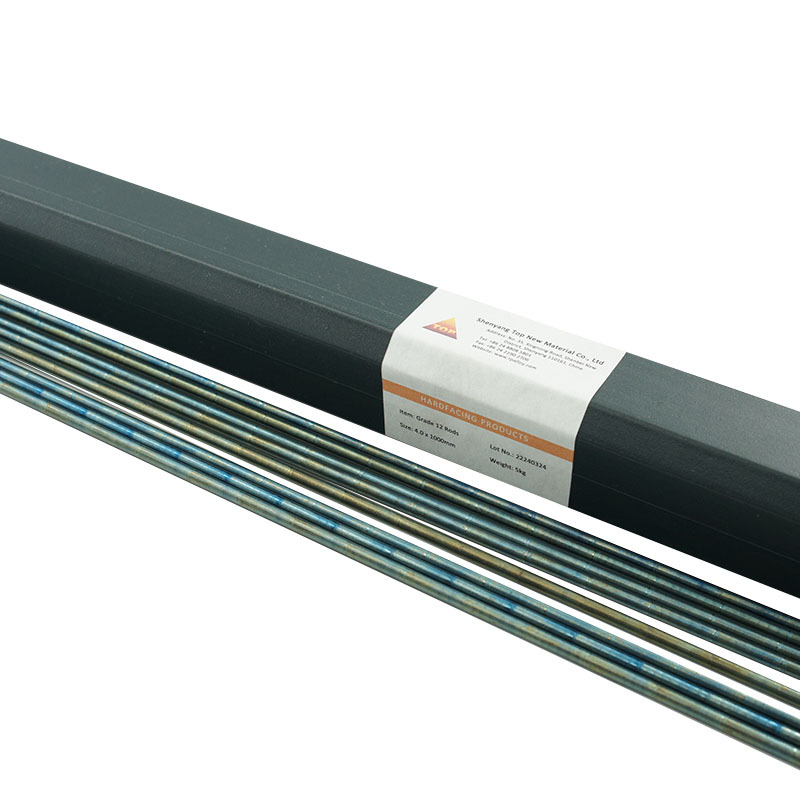

AWS A5.21 Cobalt Alloy 12 welding rods, expertly crafted from cobalt-based alloys. These rods are highly versatile, tailored for wear-resistant applications, spraying techniques, and hard-facing processes. SYTOP offers a comprehensive selection, including cobalt alloy 12, in various standard dimensions ranging from D2.7mm to D6.4mm, with a default length of 1m. With ample stock availability, we also specialize in custom solutions, ensuring precise outcomes for our discerning clients.

- TNM

- China

- 1 week

- 5000kgs+/month

- Information

AWS A5.21 Cobalt Alloy 12 welding rods

The ERCoCr-B Welding Rods, part of our cobalt-based alloy series, are designed for wear applications, spraying processes, and hard-facing applications. Now Cobalt alloy 12 welding rod is currently the most widely used in the woodworking industry.

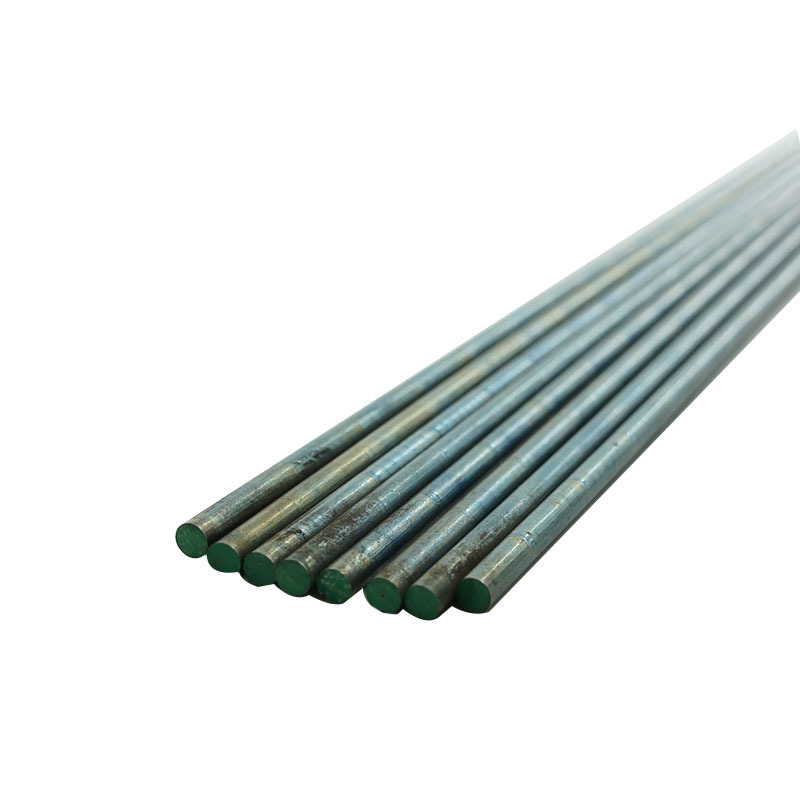

AWS A5.21 ERCoCr-B Welding Rods are produced using horizontal continuous casting, ensuring excellent surfacing performance. They exhibit high-temperature strength, wear resistance, and impact resistance.

Cobalt Based Alloy Welding Rod is supplied in the following forms:

As-Cast: Meets most hardfacing requirements.

Densified: Hipped to eliminate centerline porosity.

Ground/Finished: Eliminates surface imperfections.

Applicable Processes:

Oxy-Acetylen Tungsten Inert Arc (TIG)

Standard rod diameters include:

2.7 mm, 3.2 mm, 4.0 mm, 5.0 mm, 6.0 mm, 6.4 mm. Custom sizes available upon request.

Advantages of cobalt alloy welding rods:

Produced by horizontal continuous casting.

Excellent surfacing performance.

Has good high temperature strength and good wear resistance, high-temperature resistance, impact resistance and certain corrosion resistance.

Applications:

Argon arc welding, oxyacetylene welding, etc.

It can be used for surface treatment of parts and components in extrusion dies, turbine blades, exhaust valves of internal combustion engines, oil drilling tools, marine engineering, petroleum industry, coal, oil refining, chemical engineering, boilers and other industries.

Chemical compositions and properties (%)

ERCoCr-B Welding Rods have a chemical composition that includes Carbon (1.1-1.7%), Manganese (1.0%), Silicon (≤1.0%), Chromium (28.0-32.0%), and others. They have a hardness rating of 44-49 HRC.

| Brand | C | Mn | Si | Cr | Ni | Mo | W | Co | Fe | Hardness(HRC) |

| ERCoCr-C | 2.2-2.8 | - | ≤2.0 | 29.0-33.0 | ≤3.0 | ≤1.0 | 11.0-14.0 | Bal. | ≤3.0 | 51-55 |

| ERCoCr-A | 0.9-1.4 | 1.0 | ≤1.5 | 27.0-31.0 | ≤3.0 | ≤1.5 | 3.5-5.5 | Bal. | ≤3.0 | 38-44 |

| ERCoCr-B | 1.1-1.7 | 1.0 | ≤1.0 | 28.0-32.0 | ≤3.0 | - | 7.0-9.5 | Bal. | ≤3.0 | 44-49 |

| ERCoCr-E | 2.0-3.0 | 1.0 | ≤1.0 | 25.0-39.0 | 1.75-3.75 | 5.0-6.0 | - | Bal. | ≤3.0 | 56-60 |

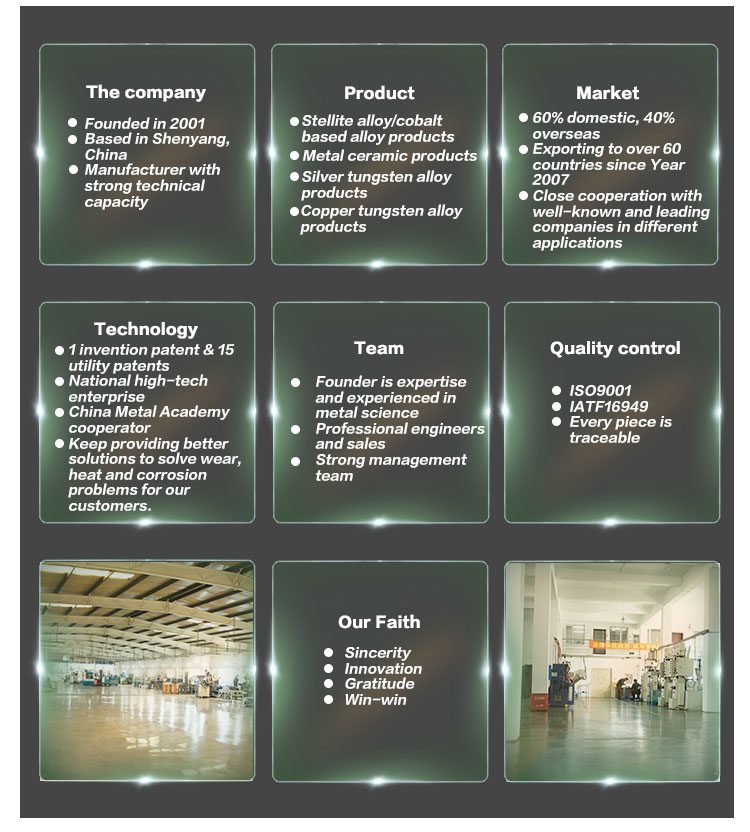

SYTOP cobalt-based alloy is a range of cobalt-chromium-tungsten alloys with wear resistance, corrosion and high thermal resistance. It is widely used in oil & gas, machinery, wood cutting, automotive, paper and food processing industry etc.

More details about cobalt chrome round bar please do not hesitate to contact me .