stellite 6 VS stellite 12

2022-12-05 12:59There are not too much difference between stellite 6 and stellite 12.

Data sheet

NO. | C | Mn | Si | Cr | Ni | Mo | W | Co | Fe | Density |

| stellite 6 | 0.9-1.4 | ≤1.0 | ≤1.5 | 27-31 | ≤3.0 | ≤1.5 | 3.5-5.5 | Bal. | ≤3.0 | ≥8.35g/cm3 |

| stellite 12 | 1.1-1.7 | ≤1.0 | ≤1.0 | 28-32 | ≤3.0 | - | 7-9.5 | Bal. | ≤3.0 | ≥8.40g/cm3 |

The range of stellite 6 hardness is HRC39-43.

The range of stellite 12 hardness is HRC47-51.

Typical Applications

stellite 6 is the most widely used of the wear resistant cobalt-based alloys and exhibits good all-around performance. Stellite 6 is ideally suited to a variety of hard-facing processes and can be turned with carbide tooling. Examples include valve seats and gates, pump shafts and bearings, erosion shields, and rolling couples. In the valve industry, Stellite 6 and 12 are often used together.

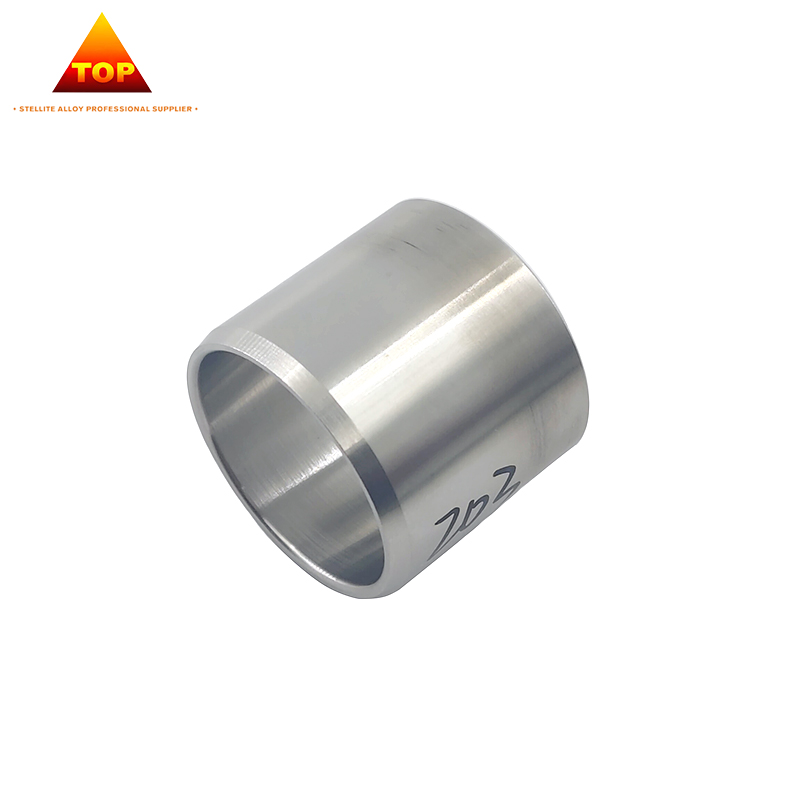

The Using of stellite 12 inclding kinves for cutting; saw tips in the wood cutting industry; hardfaing of engine valves; bearing bush as valve parts; pump parts, etc.

The showing of some products.

We can also supply many other customized products, if you have interest, leave mesage to us.